Raw Material

Polypropylene is one of the most significant thermoplastic raw materials used in plastic industry today. Its usage varies from production of plastic films, textile and plastic components for cars.

Polypropylene is considered one of the best and cost-efficient plastic materials in terms of multi-purpose applications. The demand for it is increasing and is taking the place of other plastic products.

Polypropylene is everywhere, shaping and driving our lives. It has a comprehensive range of PP grades for every application.

PP RAFFIA grades are used for applications like woven bags & fabric, geo-textile, bulk handling & packaging as jumbo bags, ropes and primary carpet backing, etc.

Raffia is one of the most important applications of Polypropylene for bulk packaging. Raffia grades are high performance material and are suitable to produce high tenacity raffia tapes. The most common methods used to produce raffia tapes are water bath quenching or chill roll casting followed by tape stretching and winding. Raffia grades exhibited excellent processability on high speed tape plants and balanced tape properties (desired tape tenacity and elongation) for wide range of tape deniers.

- TASNEE Raffia grades are used for different end-products such as FIBCs/jumbo bags, geotextiles, ropes, carpet backing fabric, woven sacks for packing food grains, sugar, fertilizers, cement, leno bags for vegetables and horticultural products, tarpaulins and general purpose wrapping fabric.

- Primary Carpet Backing:

Polypropylene woven fabric has increasingly replaced jute as the primary carpet backing in tufted and needle felt carpets. Primary carpet backing is considered as the portion of the carpet that holds the tufted piles. - Packaging Fabrics / Bags:

Within the last 10 years, polypropylene woven bag and fabrics has become more prevalent in the bulk packaging sector. Some of the current products are woven sacks like small bags (10 kg, 25kg, 50 kg), jumbo bags (1-2.5 tons) or wrapping fabric /bale wraps. - Geotextiles:

A geotextile is a woven fabric that is designed to stop water, erosion and cracking in roads, soil embankments and other construction applications. It works by reducing the amount of water in contact with the considered surface and by stopping soil migration.

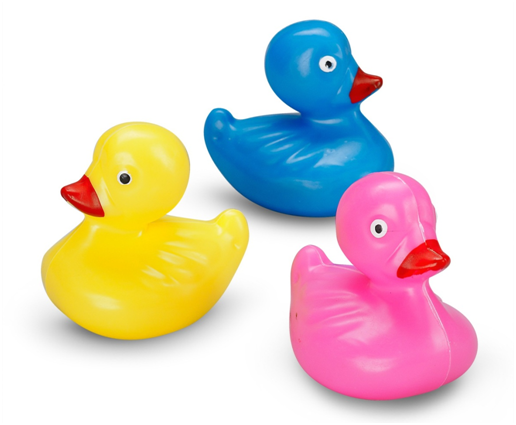

PP MOULDING grades are used for applications from containers to toys, garden furniture and closures, etc.

PP injection moulding grade for a variety of injection moulding applications.

Closures for jars and bottles

Polypropylene dominates this market due to optimum properties. Most closures are homopolymer but co-polymers might be used when higher impact strength is required. Antistatic characteristics have been found to be beneficial.

Housewares

The most widely used applications for PP are: thermos bottles and lids, double wall mugs and bowls, insulated food covers, cafeteria serving trays and food storage containers.

Plastic toilet seats

Polypropylene is used for this application due to excellent chemical resistance, scratch resistance and low cost production. It is particularly used for commercial and hospital applications.

Garden furniture

Polypropylene is a widely used material in this segment and is also used for school and office chairs.

Major Appliances: Washing machine parts are made of PP such as agitators, water pumps and bleach dispensing parts. Pumps, silverware baskets, detergent cups and door liners of dishwashers are also manufactured using PP.

PP THERMOFORMING grade is used for disposable products, trays, beverage glasses and food packaging.

Thermoformed food packaging is essential to the modern food supply chain. From cups, trays and microwaveable containers to sandwich packs, margarine tubs and non-food packaging like displays and containers polypropylene thermoforming packaging is an indispensable part of daily life.

PP thermoforming grade, offers excellent processing behaviour combined with high stiffness, excellent transparency and improved isotropic dimensional stability.

The major applications include:

Food Packaging

Fruits and vegetables containers, case-ready meat/cheese/fish packaging, containers and trays for in-store baked goods, sandwich packs, margarine tubs

Microwaveable Containers

PP is used for microwaveable containers as it can withstand sterilization, hot fill & microwave operation.

Beverages Containers

PP is used for beverage cups lids, containers, fruit juice & mineral water.

PP CAPS & CLOSURES grade is suitable for caps & closures in most demanding applications like carbonated soft drinks & waters.

PP grade is used for caps & closures in most demanding applications like carbonated beverages and water. This grade is easy processable by extrusion compression moulding. PP grade fulfils the requirements i.e. stiffness, optimum opening torque, gas retention and dimensional stability.

The major applications include:

Carbonated Beverages Bottle Closure:

PP offers adequate creep resistance and good gas retention as required by carbonated beverages closure.

Juice /Water Bottle Closure:

PP grade is used for closure of juices, energy drinks & water bottles.

- 16

- Jul

LD Polyethylene is produced with a density ranging from 0.910 and 0.940g/cm3. It is known for its low tensile strength and high ductility which makes it ideal for production of plastic bags and wrapping films.

LDPE produces four different low density polyethylene film grade with melt flow rates (MFR) range of 0.25 – 4.0 g/10min. T LDPE grades exhibit mainly excellent dart impact, high puncture & tear resistance, shrinkability and saleability.

Major applications include:

- Heavy duty packaging, shrink wrap film, agricultural film, etc.

- Medium duty packaging, shrink wrap film etc.

- Bags, pouches, food packaging lamination film, shrink film, etc.

- Lamination film, laundry bags, shrink film, food packaging pouches, etc.

- 17

- Jul

HD Polyethylene has a density of more than 0,941g/cm3. It is known for its resistance to some chemicals. It is used for the production of cables, packing material, production of milk containers, detergent bottles, food product containers, waste baskets, pipes, and water hoses.

HDPE for high quality applications such as:

Pressure pipes / high quality film / containers / drums / cans

The technology used is the most advanced technology to make multi model high density polyethylene resins.

The advantages of the technology:

- High stiffness and improved resistance to stress cracking

- Multi modal with high to very high molecular weight ends

- Online grade change without production shutdown

- Tailored properties to suit special applications

HDPE PE100 for Pressure Pipes

The market for high density polyethylene (HDPE) pipes continues to expand across a variety of applications. In particular, PE 100 resin has become the standard material for pressure pipes used for gas and water transportation due to its outstanding properties over the conventional materials.

HDPE Pipe Resins Grades and Applications

- PE 100 Black Water & gas pressure supply, sewage, drainage, industrial and agriculture pipes

- PE 100 Blue Drinking water supply pipes

- PE 100 Orange Gas supply pressure pipes

The key properties achieved by using resins for pipe applications are:

- Excellent mechanical properties

- Good toughness

- High stress cracking resistance

- High rapid crack propagation resistance.

- High stiffness

- High creep rupture strength

- Easy processability

Film Applications

High density polyethylene Film made exhibits high stiffness and impact properties. The resins can be easily processed in typical blown film lines with narrow thickness tolerances, very low gel levels and good mechanical properties. The thickness of the film can go down as low as 8 μm.

Major applications include:

Shopping bags, bin liners, carry bags, paper like, labels, etc.

Blow Molding Applications

This grade is designed for small blow molding containers up to 5 liters for food and consumer applications and provides: excellent features, lower processing temperature, uniform thickness and stable weight of bottles. This grade exhibits good mechanical properties and improved environmental stress cracking resistance.

Major applications include:

Food Packaging

Water, fruit juices, edible oil bottles

Household & Industrial Chemicals (HIC):

Chemicals, cosmetics, pesticides, lube oil, detergents containers