HD Polyethylene has a density of more than 0,941g/cm3. It is known for its resistance to some chemicals. It is used for the production of cables, packing material, production of milk containers, detergent bottles, food product containers, waste baskets, pipes, and water hoses.

HDPE for high quality applications such as:

Pressure pipes / high quality film / containers / drums / cans

The technology used is the most advanced technology to make multi model high density polyethylene resins.

The advantages of the technology:

- High stiffness and improved resistance to stress cracking

- Multi modal with high to very high molecular weight ends

- Online grade change without production shutdown

- Tailored properties to suit special applications

HDPE PE100 for Pressure Pipes

The market for high density polyethylene (HDPE) pipes continues to expand across a variety of applications. In particular, PE 100 resin has become the standard material for pressure pipes used for gas and water transportation due to its outstanding properties over the conventional materials.

HDPE Pipe Resins Grades and Applications

- PE 100 Black Water & gas pressure supply, sewage, drainage, industrial and agriculture pipes

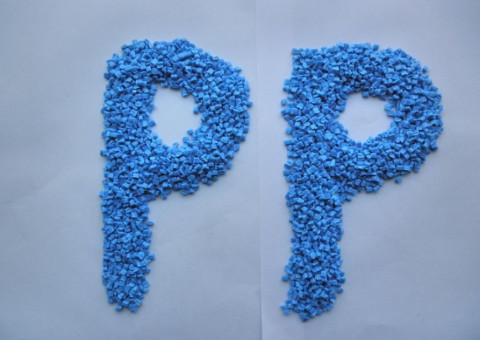

- PE 100 Blue Drinking water supply pipes

- PE 100 Orange Gas supply pressure pipes

The key properties achieved by using resins for pipe applications are:

- Excellent mechanical properties

- Good toughness

- High stress cracking resistance

- High rapid crack propagation resistance.

- High stiffness

- High creep rupture strength

- Easy processability

Film Applications

High density polyethylene Film made exhibits high stiffness and impact properties. The resins can be easily processed in typical blown film lines with narrow thickness tolerances, very low gel levels and good mechanical properties. The thickness of the film can go down as low as 8 μm.

Major applications include:

Shopping bags, bin liners, carry bags, paper like, labels, etc.

Blow Molding Applications

This grade is designed for small blow molding containers up to 5 liters for food and consumer applications and provides: excellent features, lower processing temperature, uniform thickness and stable weight of bottles. This grade exhibits good mechanical properties and improved environmental stress cracking resistance.

Major applications include:

Food Packaging

Water, fruit juices, edible oil bottles

Household & Industrial Chemicals (HIC):

Chemicals, cosmetics, pesticides, lube oil, detergents containers